Exterior: Remove Sail Panel and Glass on a Stealth (Rear Quarter Window)

Many stealth owners prefer the look of the 3000gt sails but this involves removing the sail panel and glass on the Stealth. It can be tricky but after doing one side the other side took 10 minutes. Aside from basic hand tools you will need a window removal tool. I bought this one from harbor freight. If you get your own either make or make sure it has the pusher knife to push the wire through the seal.

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=96339

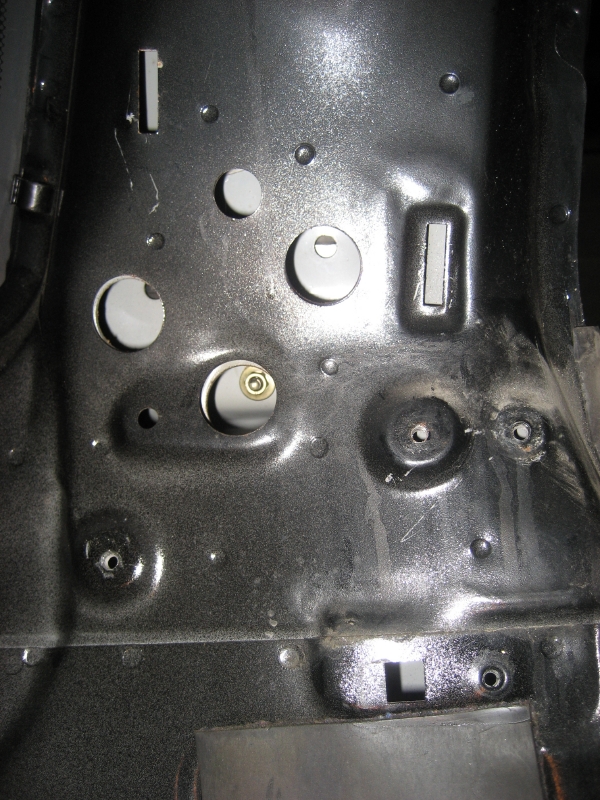

Start by removing the interior panels. This is not included because directions can be found elsewhere. I believe on stealth316.com. Then pull out the door frame rubber seal. You will see the chrome trim screwed in that holds the seal. Unscrew this and remove.

Next unscrew the screws holding the painted front window trim piece.

You will then need to unbolt the sail panel itself. There are 10mm nuts inside and one screw on the outside. After unbolting, (make sure you get all of them!), it should pull out. It's sealed in aa couple places so it might be tough. It also likes to catch the threads in the bolt holes. I found it easier to pull the top out a bit first, then push the studs on the bottom out because prying on the plastic didn't seem safe.

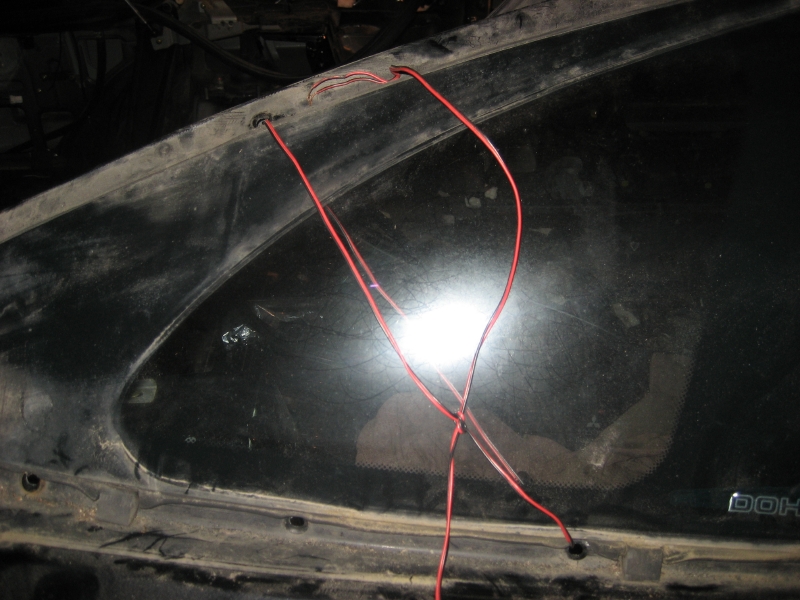

Ok. Now for the window glass. The basic idea is to thread the wire with the knife tool between the body and the glass so it can be "sawed" out. The best way to setup the wire tool is to thread one handle into a large length of the wire without cutting it. This allows you to adjust the length to whatever feels comfortable.

Start by pushing the knife inbetween the glass/body. You will want to angle the knife down into the body to avoid scratching the glass. Work it in and out a few times to make sure you have a good hole started. Then pull it out and fish one end of the wire in.

Next saw the wire up to the top right corner until the inside wire hits the metal and can't go any further. It helps to do it semi quickly to heat up the wire and have it melt through the seal. Be sure to angle the wires toward the inside of the car and away from the glass because the braided wire will ruin the glass.

Turn the wire around the other way and head down to the back of the car and stop down in the corner again.

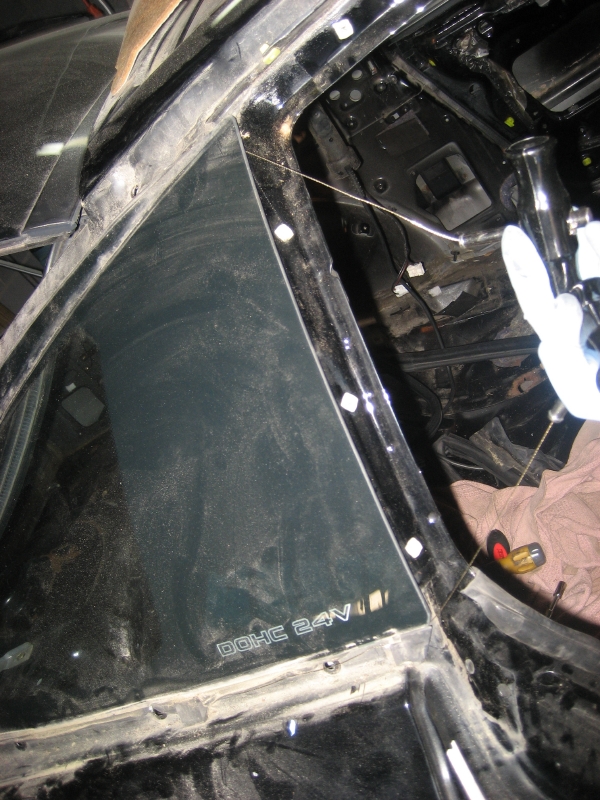

Now you want to make it around the curved corner. Using a knife cut a slit in the rubber as close to the body as possible. This will hold the wire and keep it away from the glass. Then pull the outside wire to the right and make sure it's close to the body. Also make sure it's under the square rubber separators. Then saw away. It helps to have the wire long enough to reach in the door frame.

Once you hit the lower right corner you can stop. Pull the inside wire's handle off and fish it up through the seal at the top. You shouldn't need the knife tool to do that.

Before finishing the cut, tape or wire the glass so it doesn't fall.

Then finish sawing your way until the wire pulls all the way out. Be sure to go underneath the square rubber pieces.

All done!